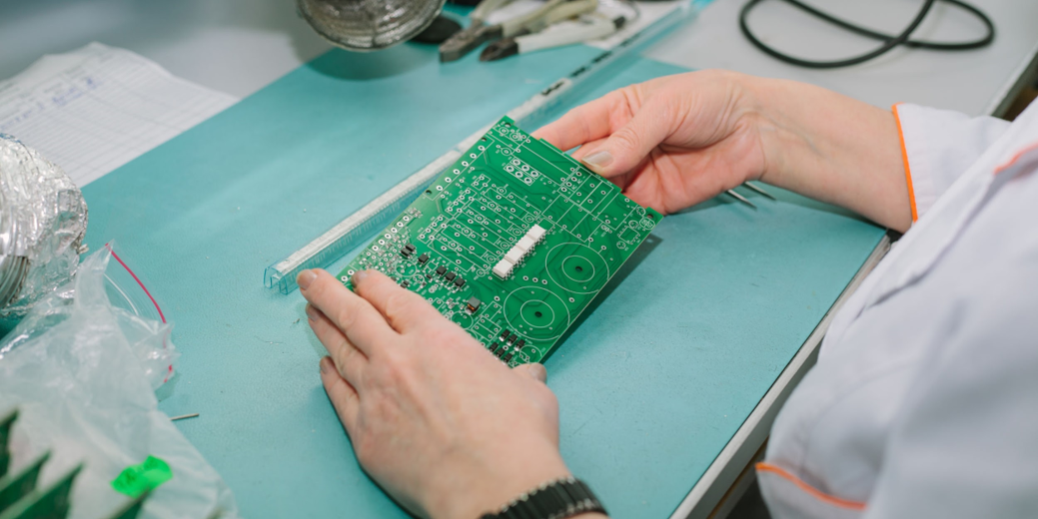

Printed circuit board manufacturing and printed circuit board assembly are two different disciplines and each of them has a unique set of processes not applicable to the other.

Many people make the mistake of referring to printed circuit board manufacturing as printed circuit board assembly and vice versa. The former refers to the fabrication of bare PCBs while the latter refers to the placement or installation of components on bare PCBs. In most cases, PCB manufacturing and assembly are performed by different companies although there are a few that do both.

It is imperative for PCB-assembling companies to install measures to detect defects during the production stage. Failure to detect such flaws can cost you, the manufacturer, thousands of dollars in fault diagnosis, cost of repair or rework, and lost production time. Ascertain the quality of your PCB assemblies with these quality assurance measures:

1. Make sure that your PCB assembler is IPC certified.

The Association Connecting Electronics Industries, formerly the Institute for Printed Circuits (IPC), is an organization of players and stakeholders in the electronic industry around the world. It assumes the responsibility of setting quality standards for the design, manufacture and assembly of printed circuit boards. The organization is also responsible for the screening and approval of IPC certification centers.

Some of the the most important standards of quality involved in PCB assembly include:

IPC-A-610

IPC-A-610 is the title given to “Acceptability of Electronic Assemblies.” It is the most popular and widely accepted standard that is used to define what’s acceptable and unsatisfactory in the PCB assembly industry. IPC-A-610 allows for the adoption of a common quality standard between electronic manufacturing services providers, electronic manufacturers, and original equipment manufacturers.

An Individual certified in this standard is qualified to become an IPC certified trainer in the acceptability of electronic assemblies.

The IPC-A-610 certification is suited for people who are responsible for the reliability and quality of electronic assemblies including managers, engineers, production staff, and quality assurance personnel.

J-STD-001

IPC-J-STD-001 is the title given to “Requirements for Soldered Electrical and Electronic Assemblies.” As its name implies, this standard enumerates the requirements for the manufacture of electrical or electronic assemblies. Methods, materials and verification criteria are some of the important elements necessary for the manufacture of quality electrical and electronic products. One of its most significant roles in the manufacturing cycle includes process-control. It is also responsible for setting industry approved requirements for various electronic products.

Like the IPC-A-610, the J-STD-001 is appropriate for people who are responsible for the assurance of the quality of soldered electronic assemblies.

IPC-7711/7721

IPC-7711/7721 is the title given to “Rework of Electronic Assemblies/Repair and Modification of Printed Boards and Electronic Assemblies”. It serves to confirm the knowledge and capability of an individual to train others on repair and modification techniques of PCBs and electronic assemblies.

This standard and training certification is appropriate for individuals involved in quality assurance, manufacturing, and training departments of an organization. It gives certified individuals the ability to conduct rework on electronic assemblies in-house instead of having the products reworked by an outside contractor.

2. Do a careful evaluation before sending your PCB Assembly Overseas

The low cost of an offshore assembly could be too tempting to resist, but if you consider the risks, you will realize that you’re making yourself vulnerable to quality issues. There’s no guarantee that an overseas assembler won’t cut corners or use substandard materials, especially if they don’t have the proper IPC Certifications. Quality issues can trigger board problems that will eat up the low cost you were attracted to in the first place.

3. Ensure the Consistency of your labels.

Labels matter in the electronic manufacturing industry! Make sure that the labels on your components are consistent with your design and have all parts clearly labeled and numbered.

4. Rank features according to importance.

As a PCB assembly manufacturer, you may be craving to load your small boards with as many features as you possibly can. Unfortunately, it’s not always possible. In order to achieve the best outcome, list down the features you want and rank them based on what you believe is important. Ask your PCB manufacturer to help you improve your design and get the outputs you think are most important.\

5. Plan sufficient lead times on all stages of the assembly process.

Allocating lead times is an important part of systematic processes. It shouldn’t be assumed, but carefully planned. When determining lead times, you should consider the type of project and whether it’s new or a repeat order. Consider longer lead times for new designs taking into consideration the different steps involved in the process.

6. Give importance to file formats.

An essential part of PCB assembly is making sure that your PCB manufacturer is an expert in the file formats you want to submit. Your failure to do so can cause unnecessary delays to your project.

PCB assembly is a complicated process and ensuring quality can be especially challenging in the absence of quality standards. To get the quality you desire, you must embrace the need for quality standards. Recognize your need for IPC certification and send key personnel to IPC certified training centers like Blackfox to enhance their quality awareness and skills.

Call us at (303) 684-0135 ext. 208 for your inquiries.