2020 was a year of unprecedented lockdowns that were implemented to control the outbreak. These then sparked simultaneous massive economic repercussions all over the world. For the electronics industry especially, it has been one turbulent year.

Fortunately, 2021 gave the world a chance to hit the reset button. This article will talk about the electronic manufacturing trends that will dominate 2021 and how by utilizing an electronic manufacturing industry consultancy service, EMS companies can leverage these trends to recover from the 2020 recession and have a commanding position in the industry.

1. Emerging Technologies

First, in this list are emerging technologies, which have gained traction in 2020, and will become the new normal in 2021 and beyond. Most of these aren’t new, but they significantly impacted a year full of lockdowns, social distancing, and work from home initiatives.

3D printing is one thing that comes to mind. Prototypes for expensive products can be created much faster because of this technology and for lesser costs. This made it easier for design teams to implement tests and make modifications during the initial design process. Simply said, 3D printing changed prototyping forever.

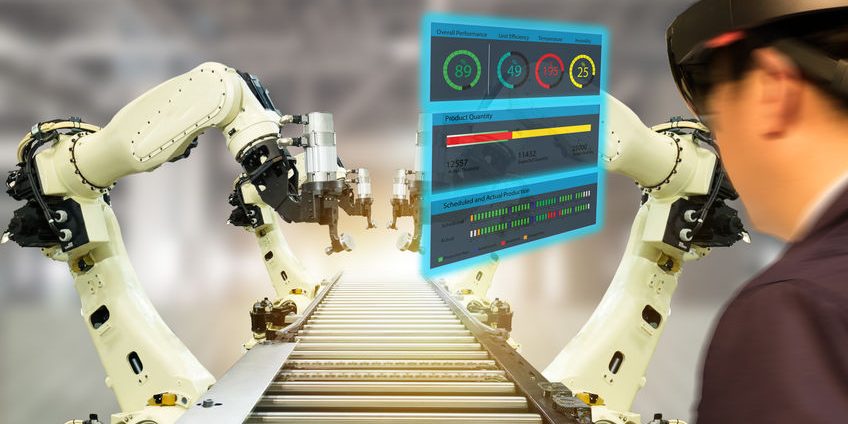

Another technology that came into the limelight in 2020 was Augmented Reality AR and Virtual Reality VR due to many people forced to stay in their homes. Many turned to AR and VR to escape the stress of the real world. This was one way these technologies made an impact, but outside of the entertainment context, they helped a lot of industries deal with the effects of the Coronavirus. Doctors used AR headsets to treat high-risk COVID-19 patients. Remote support engineers used similar headsets to guide customers in performing remote maintenance tasks.

Electronic design itself greatly benefited from these technologies, especially in Advanced Computer-Aided Design (CAD). AR and VR allowed designers to preview any product virtually to make modifications and improvements before the production phase. As a result, they were able to create production-ready designs, boosting design efficiency and productivity.

The pandemic of 2020 forced these technologies to the center stage last year, and they are here to stay. With support and guidance in design and engineering, electronic manufacturing industry consultants can help manufacturers maximize these technologies’ use.

2. Knowledge Workers

At the height of the pandemic in early 2020, people shifted to working remotely, and only robots and automatic systems remained to carry out manufacturing and cleaning tasks.

Robots’ ability to handle an endless amount of repetitive and tedious tasks in a day will allow the human element of the workforce to focus on other more critical tasks. This trend will require more knowledge workers with tech skills. Without a doubt, robotics, artificial intelligence, and automation will remain a focal point of manufacturing in 2021.

3. Resiliency Strategies

What was once a vital part of business strategy, disaster recovery will soon be replaced by resiliency strategies in 2021, as COVID-19 rendered disaster recovery plans useless at the outset of the pandemic.

We saw most of the world’s industries shift to working remotely. Long term resilience will be the key moving forward, and it will be centered around remote management of production floors.

This shift will require newer and better networking technology and smart manufacturing equipment.

Conclusion

Knowing these trends can help EMS companies come up with better strategies for 2021 and beyond. By hiring electronic manufacturing industry consultants, you can better incorporate these trends to your benefit.

For your electronic manufacturing industry consultancy service needs, contact us at 888-837-9959 or email Sharon at [email protected] for more information.