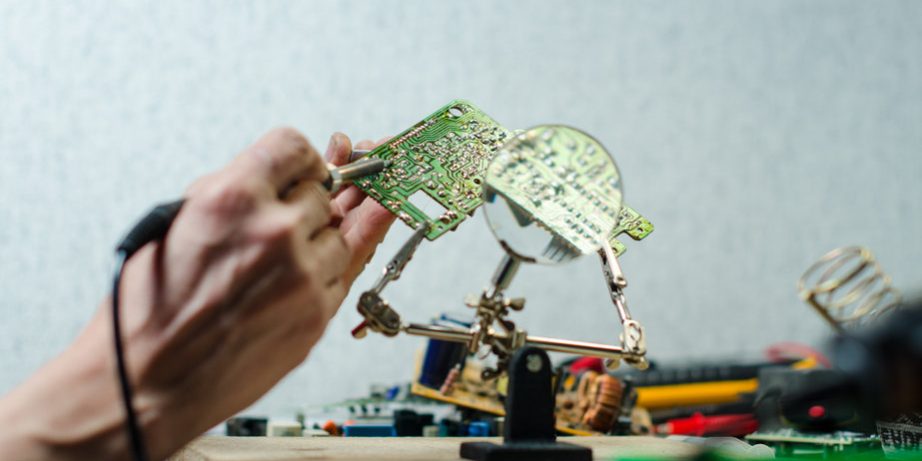

The world of robotics is one of the exciting fields for those with IPC Certification or those aspiring for a career in printed circuit board (PCB) design and assembly. The use of robots is commonly used in manufacturing and service settings across many industries. These robots are generally put into place in order to automate and streamline processes. The PCB is an essential component in robotics since the board is where electronic controls and operations are processed.

With the technological and digital advances that continue to happen these days, robotics are definitely here to stay. You can even find robots in homes already such as smart robotic vacuum cleaners, light and HVAC settings controlled by artificial intelligence, and other automated systems in the house.

After completing your on-site IPC training, you’ll definitely want to know what we can expect from the field of robotics in the future. Below are some of them.

Sales of service robots are expected to rise vs. industrial robots

Service robots are those that perform tasks which humans find time-consuming, dirty, boring and/or tedious while industrial robots are those that basically automate manufacturing processes. The Association for Advancing Automation, citing an International Federation of Robotics (IFR) report, reveals that the growth rate of the service robot sector is expected to be much higher than the industrial robot sector. More specifically, sales of service robots in logistic applications are expected to reach 259,000 units by 2023. This is followed by public environments application (76,000 units) and defense applications (33,000 units).

Many companies worldwide are expected to implement automation with multiple robot fleets in their businesses. This means that aside from electronic manufacturing workers, professional systems integrators will also be in demand in the job market in order to assist these companies to quickly implement robotics.

The cobot market is expected to exceed US$11 billion by 2030

According to ABI Research, the Collaborative Robotics market will reach more than US$11 billion by 2030, which pales greatly from US$711 million in 2019. The market share also represents 29% of the total market of the industrial robot sector.

Collaborative robots (cobots) are basically robots that can learn multiple tasks to assist humans.

Many small manufacturers are expected to ramp up their automated systems in their operations. However, these first-time robotics users will want to have robots that are convenient to program, set up and deploy. Cobots are the practical solutions with their programmable system.

Enroll in on-site IPC training and engage in electronic manufacturing apprenticeships to stay on top of the latest trends and standards when it comes to the circuitry and PCB designs for the promising cobot market.

75% of the robots shipped in 2030 will be mobile

More specifically, almost 6 million robots will be mobile out of the 8 million to be shipped in 2030, according to another press release by ABI Research. This represents the massive shift expected in the robotics industry as it moves away from fixed automation since there’s a growing interest among businesses across all industries for mobile systems.

Mobile robots are those that are controlled by software to move around its surroundings with the use of sensors and other technologies. Common applications of mobile robots in commercial and industrial settings include materials handling, warehouse management, delivery and transport. There are even new applications for mobile robots as well including painting and de-painting of large aircraft and danger assessment.

Get your Professional Certification today

The best time to prepare for the promising future of the robotics industry is NOW. Upgrade your career in the electrical manufacturing industry today by registering in one of our premier IPC Certification and Training courses.

Blackfox takes pride in its proven leadership in electronic manufacturing training, which aims to enhance individual job performance and promote best manufacturing practices.