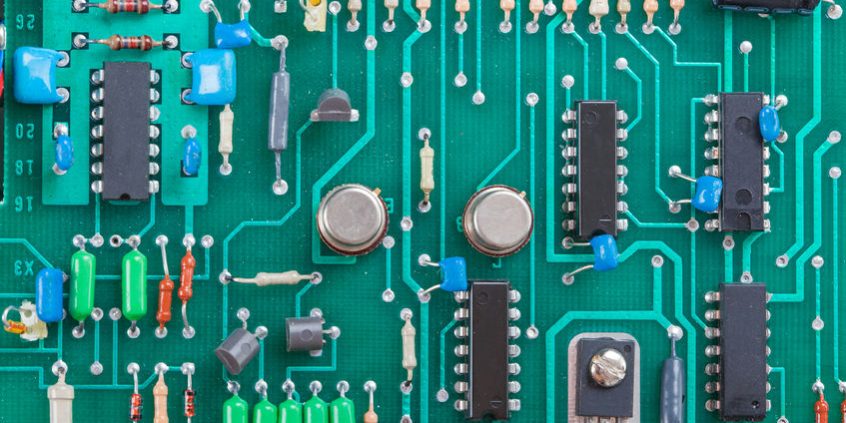

As the heart of all modern-day electronics, Printed Circuit Boards (PCBs) support and connect electronic components to make an electronic device function. And there are two main methods for mounting components onto a PCB.

In this article, you will learn about the difference between those two methods – Surface Mount Technology (SMT) and Through-Hole (TH), and which is best used in soldering for beginners.

What Is Through Hole Technology?

Through-Hole (TH) is a mounting method that involves inserting the pins or leads of electric components through the holes of the PCB (hence its name).

Through-hole technology has three types, depending on the number of pins of the component.

- Single-ended – component with pins at one end

- Double-ended – component with pins at both ends

- Pin grid array package – The component has an array of pins on both ends

Advantages Of TH

Most electronic devices are designed for human use, and we humans aren’t exactly careful when handling these devices. A through-hole connection to the PCB is more robust compared to most surface mount connections. A surface mount bond is only as strong as the solder joint that holds it to the surface of the board laminate. This becomes a problem for smaller components because this means decreasing the amount of solder to the bond which can decrease its strength.

When your product requires a much stronger connection between layers, through-hole is the best type of mounting method to use if you want to ensure the high reliability of the device. Unlike surface mount devices (SMD’s) secured only by solder on the board surface, through-hole components have leads that run through the board, making for a connection that can withstand environmental stress.

This is why through-hole technology is widely used in military, automobile, and aerospace electronics, where the conditions can be extreme – high temperatures, high accelerations, and collisions. When testing, prototyping, and soldering 101, through-hole technology also allows for easy adjustments and replacement of components.

What Is Surface Mount Technology

Surface Mount Technology (SMT) involves mounting and soldering electronic components that either have short pins/leads, or none at all, onto the surface of a PCB. This also means that the component and the solder joint are all on the same side of the PCB.

Unlike TH, SMT doesn’t require corresponding through holes for component pins. Surface mount devices are also generally much smaller than TH devices.

Advantages of SMT

Because surface mount components are designed to be soldered onto the board surface, assemblers can use both sides of the board for mounting. No space is wasted as there is no need to mount inside of larger drilled holes.

The size and footprint of surface mount components can also be miniaturized, which isn’t possible for TH.

When To Use Which Technology For Mounting And Soldering

SMT requires large and highly advanced equipment and materials such as reflow ovens, pick and place machines, and custom stencils. On the other hand, TH will only require some solder, a good soldering iron, and a pair of sturdy hands.

Since soldering SMT components tends to be a more difficult process because of their minuscule size, they are ideal for large-scale productions that require a high degree of automation and speed. For soldering 101, inexperienced or brand new soldering operators will start with TH mounting and soldering since this technology is best as a starting point before moving on to SMT soldering.

Take your employees’ soldering workmanship to higher levels. Contact us for more information about soldering for beginners at [email protected].