Electronics used to operate solely at standard temperatures. Today, it doesn’t only demand faster and more powerful circuitry, modern electronics also require boards to function in much harsher environments, including extremely high temperatures, pushing operating tolerances to their limits.

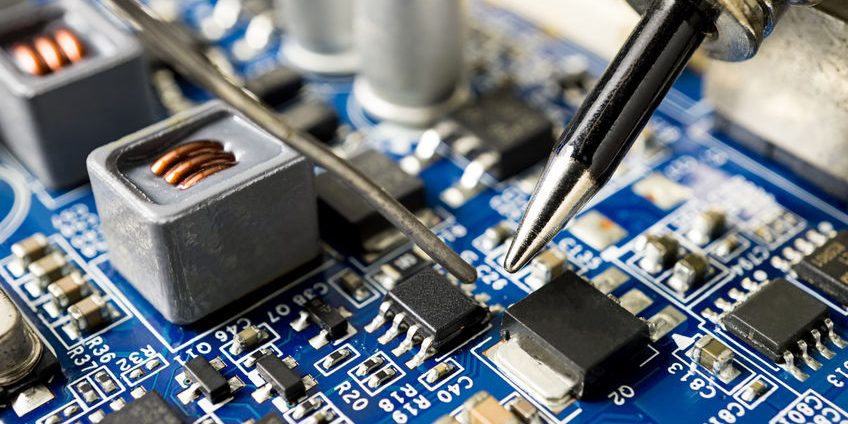

In the past, products that were not considered high-temperature electronics, like computers, are now being designed with special thermal considerations. And to make these high-temperature electronics, EMS companies need to utilize high temperature or HMP (High Melting Point) soldering, which will allow them to cater to fields that require these high temp boards. But with this type of soldering comes huge risks for possible disastrous component or board failures.

This article will discuss the four industries that need high-temperature electronics and how electronics manufacturers can better serve these industries by letting their key production staff undergo high temp solder training / HMP solder training.

1. Gas And Oil

Drilling operations have gone deeper over the years, which means that drilling and monitoring equipment are operating in hostile wells with temperatures exceeding 200 Degrees °C. During the drilling part, sensors and geosteering electronics monitor and direct the drilling equipment.

After drilling, when geologists have to evaluate the drilled hole’s condition, they use electronic measuring instruments for radioactivity and magnetic resonance. Then, once production has started, more devices are required to monitor pressures, temperatures, and vibrations – all of this while actively controlling valves.

Should any of these electronics fail, the consequences can be costly, time-consuming, and dangerous. Operating a complex offshore rig costs 1 Million USD per day, which is why downtimes are unacceptable, and you need high-temperature electronics to maintain system reliability at all times.

2. Avionics

Aircraft development always evolves together with electronics, as proven by the MEA initiative (More Electric Aircraft), which seeks to replace traditional centralized engine controllers, made up of bulky, heavy wire harnesses and complex interconnections.

With a distributed control scheme, aircraft are now hundreds of pounds lighter. On the downside, electronics are now much closer to the engines and other heat sources where the ambient temperature can sometimes go up to 200 Degrees °C.

3. Medical Instrumentation

High-reliability electronics are needed for medical applications in harsh conditions, such as autoclaves – a powerful heated machine that uses high-pressure steam to sterilize medical equipment.

Surgical tools and instrumentation need to maintain their reliability under these conditions.

4. Automotive

Like in the aviation industry, carmakers are now replacing mechanical and hydraulic systems with electromechanical or mechatronic systems, which consist of locating sensors, signal conditioning, and control electronics.

Similar to the aviation field, this shift means that electronics are now much closer to the sources of heat where the ambient temperature ranges from 200 to 300 Degrees °C. And it’s worse in electric vehicles and hybrid electrics, which depend heavily on power electronics.

Conclusion

In summary, the four industries that require high-temperature electronics are gas and oil, avionics, medical and instrumentation, and automotive. These are highly critical fields that require the toughest electronics as lives will depend on them.

EMS companies that enroll their assembly crew in HMP solder training will maximize HMP soldering in the manufacture of high-temperature electronics for the industries listed above. Your staff will gain the knowledge to strengthen their soldering skills and be updated on the latest acceptable workmanship requirements of HMP soldering.

Elevate your production quality, and meet IPC soldering standards. For a hands-on high temp solder training course, contact Blackfox today at (888) 837-9959 or [email protected].