In the year 2022, the pandemic caused by Coronavirus disease (Covid-19) will continue to have a broad influence on our life.

Here are some interesting things regarding the key trends that will have the largest influence in 2022. The most prominent trends in 2022 will most likely center on the convergence of technological trends as technologies that allow us to mix them in new and astonishing ways emerge.

Organic Electronics

Organic electronics outperform standard inorganic electronics in every way. This is due to the fact that they are inexpensive, flexible, indissoluble, optically transparent, lightweight, and demand little electricity. Furthermore, the growing awareness of the need of sustainable development and eco-friendly production encourages manufacturers to use organic electronics. As a result, it opens up new business options for organizations, giving them a competitive advantage in the long term.

Teleworking

Teleworking will expand further in 2022, delivering breakthroughs in software development. To boost employee efficiency, businesses throughout the world will need to accommodate hybrid forms of team management and collaboration. This new norm will rise even more in 2022 as the trend of holding online meetings and video sales calls continues.

Internet of Things (IoT)

This technology has been used by the electronics manufacturing sector in a variety of methods, each with its own set of advantages. Cost savings, product innovation, enhanced efficiency, and improved safety have been among the most prominent of these. The majority of organizations have made educated judgments based on the real-time data provided by these devices. When combined with other technology advances, this can assist to generate more efficient short- and long-term decisions.

Artificial Intelligence (AI)

Artificial Intelligence-powered solutions are gaining traction across many industries. AI influences the expansion of semiconductor manufacturing in two ways: first, by increasing demand for novel AI-capable electronics components, and second, by improving product production and design processes. Traditional techniques have limits in terms of redesigning product development cycles, enhancing product design processes, decreasing faults, and getting goods to market faster. However, AI is overcoming all of these restrictions.

Advanced IC Packaging

The old method of scaling a device based on Moore’s law currently has constraints. Another strategy to reap the benefits of scaling is to combine several complicated devices into a sophisticated bundle. As a result, semiconductor companies create new sophisticated IC packaging methods that enable higher silicon integration in progressively smaller packages. Furthermore, improved integrated circuit packaging optimizes production to match client demands against total costs.

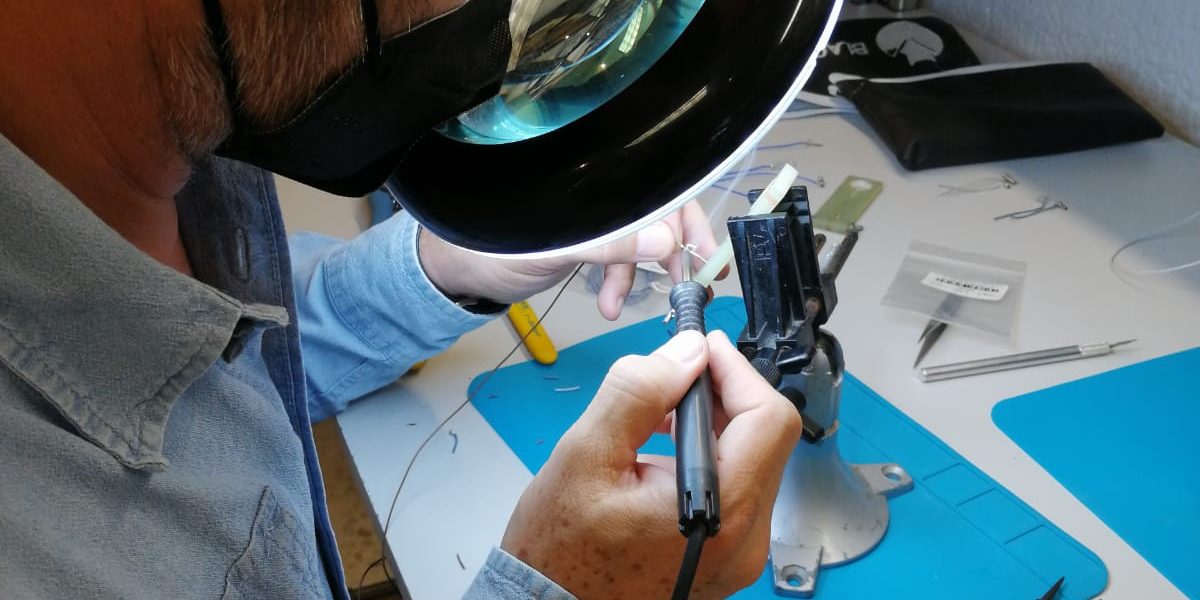

Employees in the electronics sector must have completed the IPC course and other associated electronics technician training, which is vital for companies and business owners. Thus, having an IPC certification is important.

Other companies now provide online IPC training, as we are in the midst of a pandemic. The IPC course is an excellent option for electronics manufacturing and PCB design professionals who want to reassure employers and clients about their skill level and ability.

As we look ahead to the inventive developments of the electronic manufacturing business, studying these new trends, as well as taking online IPC training, is essential in order to completely cope with the improvements.

Conclusion

The electronic manufacturing industry is changing rapidly and will continue to do so. Manufacturers are adopting new technologies and processes, which are raising the bar for production efficiency and quality. In this article, we’ve provided a few of the most notable developments in the electronic manufacturing industry in 2022. Are you now ready for these trends? Contact us today to learn how to get IPC certified.